When a patient needs a life-saving drug and it’s simply not there, the consequences aren’t theoretical-they’re immediate, personal, and sometimes deadly. In 2025, over 250 medications remain in short supply across the U.S., leaving doctors to choose between delaying treatment, switching to riskier alternatives, or telling patients they can’t get the medicine they were promised. This isn’t a rare glitch. It’s the new normal.

What Happens When a Critical Drug Disappears?

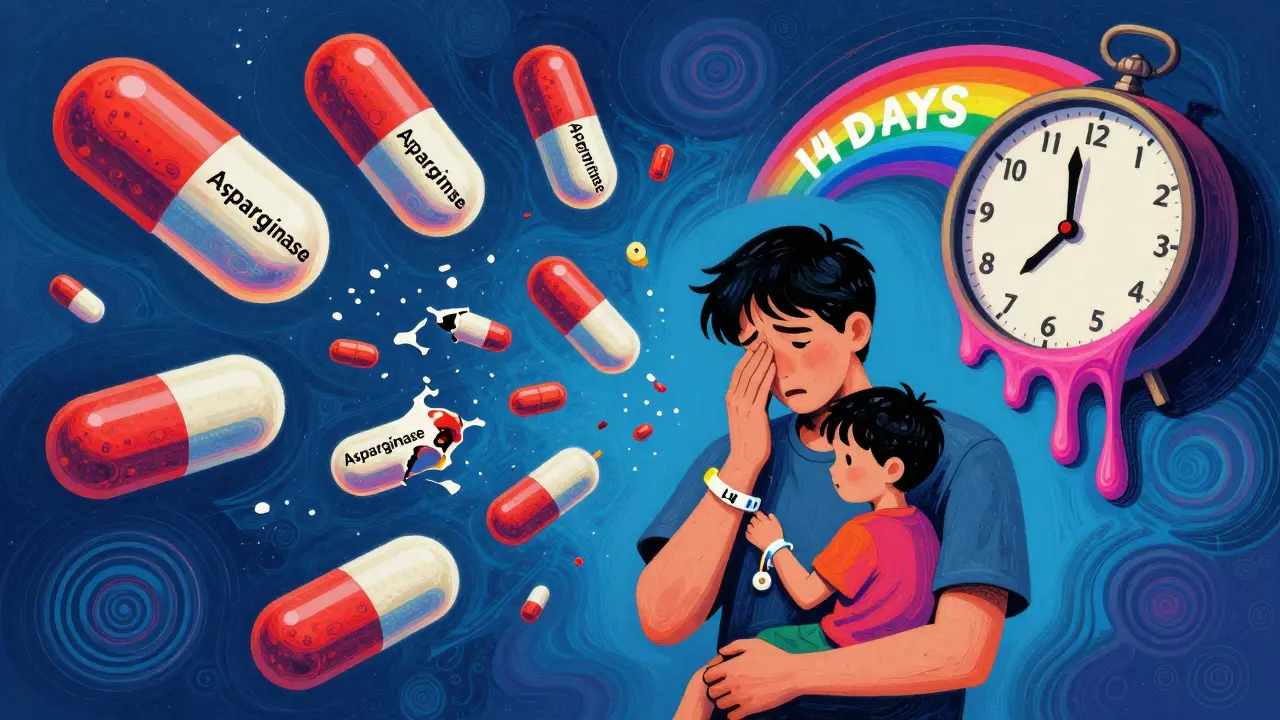

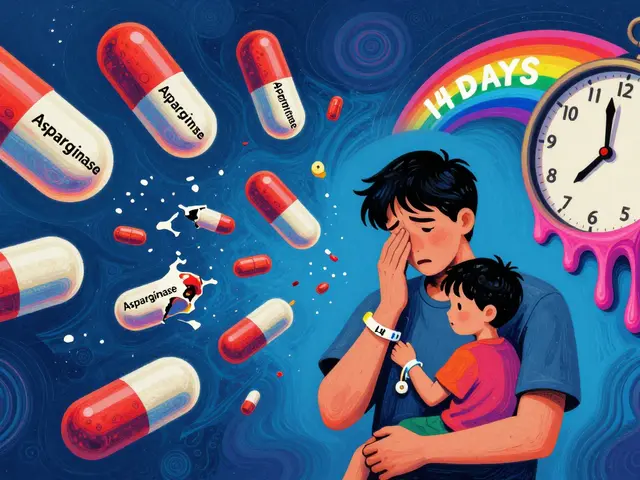

Imagine you’re a parent whose child has acute lymphoblastic leukemia. The only drug that can save them is asparaginase. But the hospital’s supply ran out last week. The next shipment is delayed by two weeks. That’s 14 days where chemotherapy stops. For a child with cancer, those two weeks can mean the difference between remission and relapse. This isn’t fiction. It’s happening right now in hospitals across the country. The same is true for patients with heart conditions who need heparin to prevent blood clots during surgery. When heparin vanishes, anesthesiologists scramble to find substitutes. Some use other anticoagulants, but those require more time to monitor, increase procedure length by over 20%, and raise the risk of complications. One cardiac center reported a 37% spike in post-op bleeding incidents during a recent heparin shortage. Oncology drugs, antibiotics, and anesthetics make up the bulk of current shortages. But it’s not just about cancer or surgery. People with chronic pain are being denied oral opioids. Diabetics are struggling to get insulin. Nurses are running out of IV saline bags-yes, the simple saltwater solution used for hydration, IV meds, and flushing lines. In 2023, 85% of hospital pharmacists had to rewrite protocols because of saline shortages.Who Pays the Price?

The burden doesn’t fall equally. Vulnerable patients-children, the elderly, those with complex conditions-bear the heaviest cost. Pediatric hospitals report 25% more drug shortages than general hospitals because kids often need specific doses or formulations that aren’t made in bulk. A child can’t take a crushed adult pill. A premature baby can’t get a standard IV bag. When those specialized versions disappear, treatment stalls. Patients are also paying more. During a shortage, alternative drugs often cost 30-50% more. Out-of-pocket expenses for patients jump by nearly 19% on average. Many skip doses, cut pills in half, or stop taking meds entirely. One study found that 31% of patients reported adverse events directly linked to drug unavailability. That’s not a side effect-it’s a system failure. And then there’s the human toll. Pharmacy staff spend 15 to 20 hours a week per shortage just trying to find replacements, train nurses, and update electronic records. That’s not time spent counseling patients or catching dangerous interactions. It’s time spent firefighting. In pediatric units, that number climbs to 25 hours. One pharmacist told me, “I used to be a clinician. Now I’m a supply chain detective.”

Why Are These Shortages So Common?

The problem didn’t start yesterday. It’s been building since the early 2000s, but it exploded after 2020. The root causes are structural, not accidental. First, most shortages involve generic drugs-medications that cost pennies to make. Pharmaceutical companies stopped making them because the profit margins are too thin. Why invest in a factory that makes $0.05 pills when you can make $100 cancer drugs? The result? Only one or two manufacturers produce a given generic drug. If one plant fails, the entire country runs out. Second, manufacturing quality issues are rampant. The FDA shut down 12 drug plants between 2021 and 2024 for failing cleanliness standards. One plant in Puerto Rico that made IV antibiotics was closed for 18 months after inspectors found mold in the production area. That one closure caused a nationwide shortage of three antibiotics. Third, global supply chains are fragile. Over 80% of active pharmaceutical ingredients (APIs) come from India and China. A single flood, political unrest, or export ban can cut off supply for months. Raw materials like heparin’s source-pig intestines-are also subject to disease outbreaks and trade restrictions.What’s Being Done-and Why It’s Not Enough

The FDA now requires manufacturers to report potential shortages six months in advance. That sounds good. But in practice, many companies wait until the last minute-or don’t report at all. The agency can’t force them to produce more. It can’t build factories. It can’t pay for more supply. Hospitals are trying to adapt. Nearly 9 out of 10 large hospital systems now have shortage management teams. Some use AI tools to track inventory and predict gaps. Group purchasing organizations like Vizient help hospitals pool orders to get better pricing. Since 2023, these efforts have saved $300 million in unnecessary spending. But these are bandaids. They don’t fix the broken incentive structure. They don’t bring manufacturing back to the U.S. They don’t solve the fact that 83% of shortages are for low-cost generics that no one wants to make.

What This Means for You

If you or a loved one rely on a prescription drug, don’t assume it’ll always be available. Ask your pharmacist: “Is this drug in short supply?” If it is, ask: “What are the alternatives? Are they safe? Will they cost more?” Keep a 30-day supply on hand if possible. Some insurers allow early refills during shortages. Talk to your doctor about switching to a different medication in the same class before the shortage hits. And if you notice delays in your treatment, skipped doses, or sudden changes in your care plan-speak up. Hospitals are overwhelmed. But if enough patients demand transparency, change becomes harder to ignore.What Needs to Change

The system won’t fix itself. Real solutions require policy action:- Financial incentives for companies to produce essential generics-even if they’re low-margin.

- Minimum stockpile requirements for critical drugs like heparin, insulin, and antibiotics.

- Investment in U.S.-based manufacturing for high-risk medications.

- Real-time public tracking of shortages, not just hospital-level alerts.

- Penalties for manufacturers who fail to report shortages on time.

What drugs are currently in shortest supply?

As of mid-2025, the most critical shortages include asparaginase (used for leukemia), heparin (for blood clot prevention), IV saline bags, nelarabine (for T-cell cancers), and several antibiotics like cefazolin and vancomycin. Anesthesia drugs such as propofol and lidocaine are also in short supply. These shortages affect everything from cancer treatment to routine surgeries and emergency care.

Can I get my medication if it’s on shortage?

It depends. Some pharmacies may have limited stock, or your doctor may be able to prescribe a different drug in the same class. But alternatives aren’t always safe or equally effective. For example, switching from one chemotherapy drug to another can reduce treatment success rates. Always talk to your pharmacist and doctor before making any changes. Don’t skip doses or cut pills without professional advice.

Why aren’t more companies making these drugs?

Most of the drugs in shortage are generics-low-cost, high-volume medications with slim profit margins. Pharmaceutical companies focus on expensive brand-name drugs that generate bigger returns. Building and maintaining a manufacturing facility for a drug that sells for pennies doesn’t make financial sense unless the government steps in with subsidies or guaranteed purchases.

Do drug shortages affect insurance costs?

Yes. When a drug is in short supply, the alternatives are often more expensive. Insurers may pass those higher costs to patients through higher copays or deductibles. Patients on Medicare or Medicaid have seen out-of-pocket costs rise by nearly 20% during shortage periods. Some drugs that used to cost $5 now cost $50 or more.

How can hospitals better prepare for shortages?

Hospitals are using automated tracking systems, forming shortage response teams, and building strategic stockpiles of critical drugs. Some participate in group purchasing organizations that share inventory across facilities. But the biggest barrier is staffing. Managing shortages takes 15-20 hours per week per drug-time that could be spent on patient care. Without more funding and support, hospitals can’t keep up.

January 21, 2026 AT 22:51

Jarrod Flesch

Man, this hit hard. I work in a rural clinic down under, and we’ve had to scramble for saline bags before. Not because we’re bad at planning, but because the supply chain’s a house of cards. One flood in India, one FDA shutdown, and suddenly nurses are rationing IV fluid like it’s gold. We’re not talking luxury meds here-we’re talking basic life support. It’s insane we treat this like a glitch and not a crisis.

Also, props to the author for calling out the ‘supply chain detective’ line. That’s the saddest job title I’ve heard this year.

January 22, 2026 AT 11:57

Malvina Tomja

Let’s be brutally honest: this isn’t a shortage. It’s a corporate betrayal. The same CEOs who cashed out on opioid profits are now letting children die because they can’t make a $0.02 pill with a 2% margin. They didn’t ‘fail’-they calculated that human lives were cheaper than factory upgrades. And now we’re supposed to applaud hospitals for ‘adapting’? Adaptation is what you do when you’re stranded on an island, not when your healthcare system is being looted.

And don’t get me started on the FDA. They inspect plants, sure. But they don’t shut down CEOs. They don’t force them to invest. They just issue press releases while kids go without chemo. This isn’t regulatory failure. It’s moral collapse.

January 22, 2026 AT 17:11

Samuel Mendoza

This is why socialism doesn't work. If drugs were market-driven, companies would make more. Simple.

January 24, 2026 AT 16:19

Melanie Pearson

While the emotional weight of this piece is undeniable, the structural analysis lacks geopolitical nuance. The U.S. pharmaceutical supply chain is not merely under-resourced-it is strategically vulnerable due to decades of offshoring driven by neoliberal trade policy. The reliance on China and India for 80% of APIs is not an accident; it is the direct consequence of deregulated capital mobility and the deliberate dismantling of domestic manufacturing capacity under the guise of efficiency.

Furthermore, the FDA’s enforcement actions, while necessary, are reactive and underfunded. The agency lacks the statutory authority to mandate production quotas or to subsidize low-margin generics. Without legislative intervention-specifically, the creation of a Public Pharmaceutical Corporation modeled after the CDC’s vaccine program-this cycle will persist. The moral outrage is valid. The policy response, however, must be systemic, not sentimental.

January 26, 2026 AT 13:19

Stephen Rock

They let kids die because someone didn't want to spend 10k on a factory

and now we're supposed to cry about it

lol

January 27, 2026 AT 08:55

Barbara Mahone

As someone who works in hospital pharmacy, I can confirm every detail here. The heparin shortage in early 2024 forced us to use a substitute that required hourly INR checks for every patient-increasing workload, risk, and cost. We lost two patients to preventable bleeds that month. No one talked about it publicly.

The real tragedy isn’t the shortage. It’s that we’ve normalized it. Nurses don’t complain anymore. They just sigh and write new protocols. Pharmacists don’t ask for help. They just work 25 extra hours a week. And the public? They assume the system works. It doesn’t. It’s just quiet about failing.

January 27, 2026 AT 11:05

Kelly McRainey Moore

I’m a mom of a kid with leukemia, and this article made me cry. We got lucky-we found a hospital with a small stash of asparaginase. But the pharmacist cried too when she told us it was the last vial in the state.

I just want people to know: it’s not just about money. It’s about sleepless nights, parents Googling ‘what if we run out’ at 3am, and kids asking why their IV looks different. We’re not asking for luxury. We’re asking for the basic promise of medicine: if you need it, it should be there.

Thank you for writing this. I’m sharing it everywhere.

January 28, 2026 AT 22:58

Gerard Jordan

Big thanks to everyone sharing their stories here. 🙏

Just wanted to add: there’s a nonprofit called Drug Supply Chain Security Initiative that’s working with 30+ hospitals to build regional buffer stockpiles of critical generics. They’re not flashy, but they’ve already prevented 17 treatment delays in the last 6 months. If you’re a healthcare worker or just care about this issue, check them out-volunteers are welcome.

And to the person who said ‘socialism doesn’t work’-maybe try thinking beyond slogans. Real people are dying because profit margins are too thin. That’s not capitalism. That’s negligence dressed up as economics.

We can fix this. But we have to choose to.